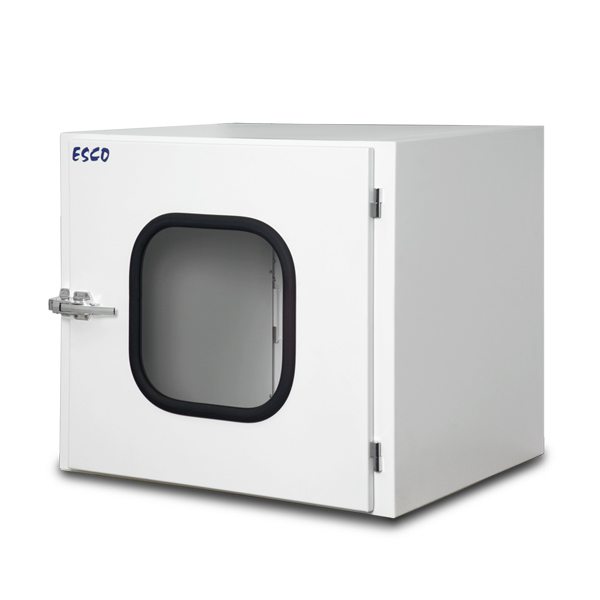

Description

Esco is a leader in air showers for demanding applications in the micro-electronics, semiconductors, pharmaceutical, spray painting, lab animal research and food markets. Esco filed its first Air Shower patent in the 1980’s and since then has installed thousands of units in diverse markets worldwide. The present Esco Air Shower is a third-generation product and features a field-programmable microprocessor control that offers the maximum application flexibility of any unit on the market.

Cleanroom Applications: The greatest source of particulate contamination in a cleanroom is the operator. Air showers are installed between change areas and the cleanroom. The air shower enhances cleanroom operating protocol by serving as a reminder to all operators that they are entering a controlled environment. Personnel therefore develop the habit of gowning up properly before entering the air shower.

Pharmaceutical and Lab Animal Research Applications: Air showers keep pharmaceutical production and lab animal breeding areas clean and also minimize egress of hazardous substances and allergens from the controlled environment.

Key Benefits:

- Disposable prefilter

- SS air nozzles

- Reduced vibration

- Energy Efficient

- Microprocessor controller

- High velocity shower jets

- Emergency stop buttons

Product Literature: cleanroom-airshower